Well, this week brought a significant amount of progress!

I was able to machine the frame rails to length, drill the mounting holes for the cylinder mount rails, as well as the rear frame (firebox cradle). In addition, I was able to machine the cylinder mount rails.

I've also assembled the locomotive frame. I learned a hard lesson - don't go to your local ACE/Dickey Bub's, just to buy a certain amount of fasteners. I spent $10 for 20 8-32 flathead screws, and when I got home, I realized I needed 16 per sideframe (for a total of 32), and so I wasn't able to complete it. As a result, I made a stop at Fastenal and picked up a box of 8-32 flathead screws (100 ct) for $8.32! Next time I need a certain amount of fasteners, I'll look up Fastenal!

The cylinder mount rails, already laid out and in the process of being center punched

Cylinder mount rails after the holes have been drilled. The Cylinder saddle holes haven't been drilled, as I want to confirm what size bolts I will be using.

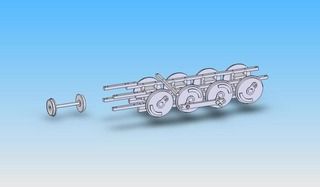

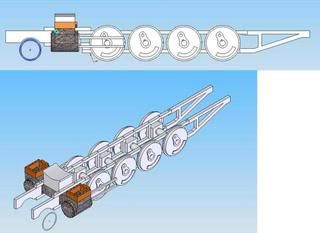

Sideframes assembled!

Cylinder saddle in place for the photo!

I've also decided that I may consider new axles for the locomotive, since I want to ensure that they are properly quartered. In conjunction with this step, I'll be re-boring the crankpin holes (probably 0.010" oversize, unless necessary) to ensure they're properly quartered. I don't want to deal with binding drivers later!

So, now my punch list is slightly smaller. The italics indicate that step has been completed.

1) drill holes in top and bottom cylinder mounts2) machine bottom cylinder mount spacer to length and drill holes.3) Machine top and bottom frame rails to length4) Obtain shim stock to install under cylinders

5) Install cylinders (determine size of screws for cylinder mounting, and fabricate if needed)

6) Clean journal boxes and lubricate with grease thoroughly --

Already cleaned, need to be rinsed with acetone/MEK, then lubricated. a. Install 2 loose bearings with sleeve retainer then do above

7) Drill axles to the bearing races on 2 undrilled axles, tap

a. Cross drill through bearing race if possible….

b. Obtain part number for bearing race for purchase of new ones with through hole if necessary

8) Check fit of journal boxes in the frame

9) Check all drivers for proper quartering. Bore out crankpin holes if needed.

10) Sandblast all drivers

11) Machine new crankpins

12) Order material for pilot support (7/16” x 1-1/2” 1018 speedymetals)

13) Figure out suspension linkage design, send to be laser cut.

14) Construct suspension linkages

15) figure out the rest of the punch list!